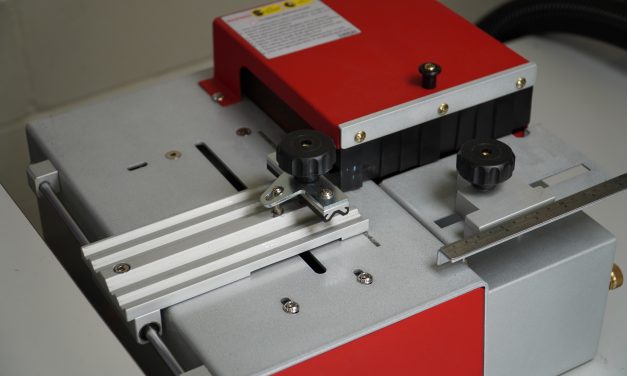

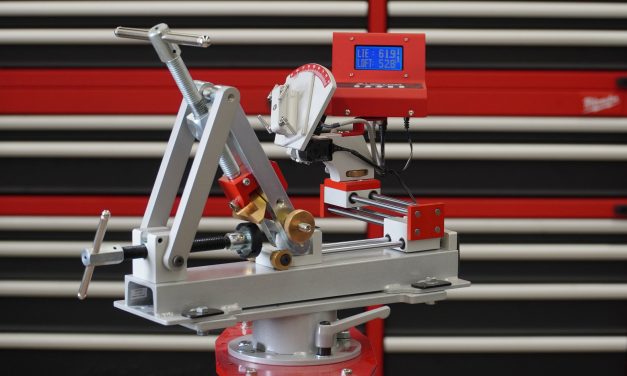

Auditor 200320 – programmable epoxy cure system

Although acrylic resins have become enormously popular for golf club bonding, at Total Fit we prefer traditionally long cure 2 part epoxy for our its longer work life and increased shear strength. The 24 hour cure time of these products limits productivity and can be compromised by temperature fluctuations during the curing process. Our 200320 curing stations accelerate the bonding process and increase the bond strength by heating the club to precise temperatures for programed time cycles allowing us to bring the clubs to full cure in one hour

Read More